Facility

Yamaco boasts three presses for hot and cold forging and is able to manufacture high-precision products

through its combined hot/cold forging technology combining both hot and cold forging processes.

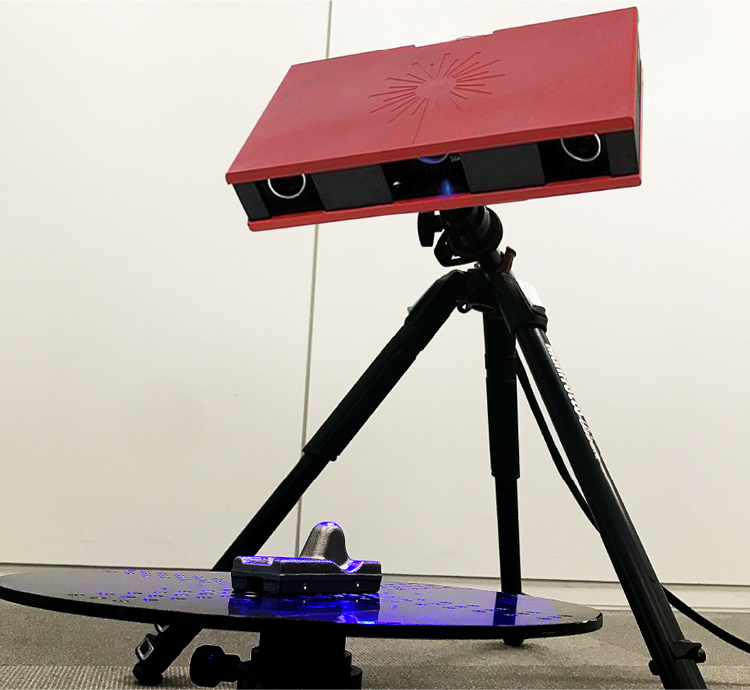

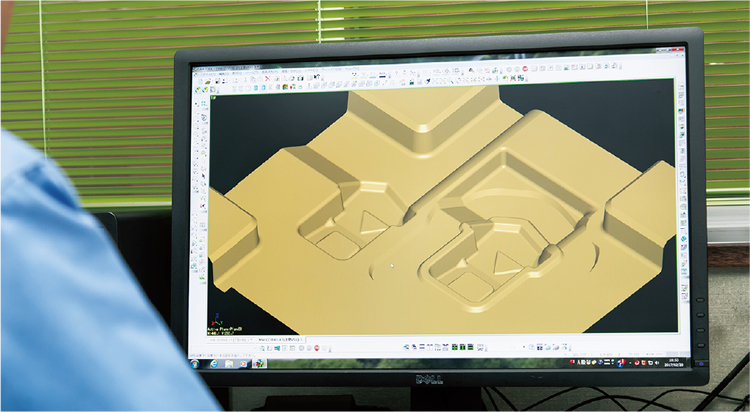

Yamaco manufactures dies in-house using 3D CAD/CAM designing and high-precision,

high-speed processing machines. This allows for improved component precision and shorter delivery times.

Using any one of a variety of processing machines such as NC lathes

or machining centers on forged products makes it possible to manufacture products

for a wide range of industries or for small lot production.

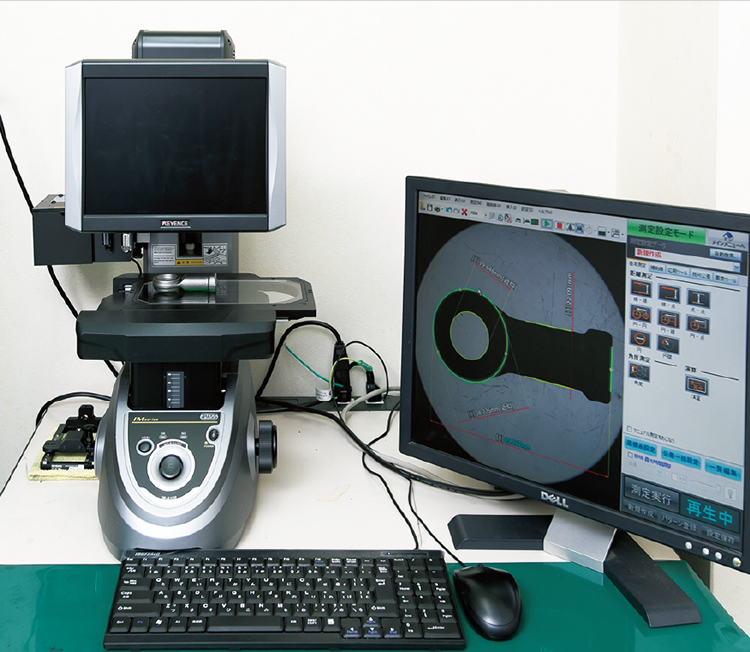

In order to meet the high demands of its customers,

Yamaco uses inspection equipment capable of accuracy down to 0.001 mm.